Hollow Cathode

-

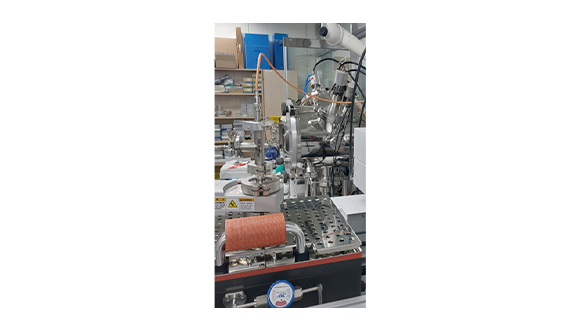

Hollow Cathode Plasma Source- Hollow Cathode Plasma Source는 Hollow cathode(cathode의 hole)를 통해 플라즈마를 발생시키는 Remote 플라즈마 소스로, 기존 CCP나 ICP 플라즈마 소스에

비해 더 높은 Plasma density 와 더 낮은 Plasma damage를 구현하며, Oxygen contamination이 거의 없는 특징을 가지고 있고, ALD, ALE, 그리고 CVD system에 효과적으로 사용될 수 있습니다. -

RF Hollow Cathode 플라즈마 소스의 특징- Custom solutions from Meaglow Ltd.

- ALD and MOCVD conversions

- Scalable plasma source (more holes = greater area)

- High electron density (>1x1012cm-3)

- Low oxygen contamination for nitride processes

- Less plasma damage than ICP

- Quick on/off

- Higher growth rates and better crystallinity than ICP for many processes

- Nitrogen, hydrogen, ammonia, nitrous oxide, oxygen, argon all trialled to date.

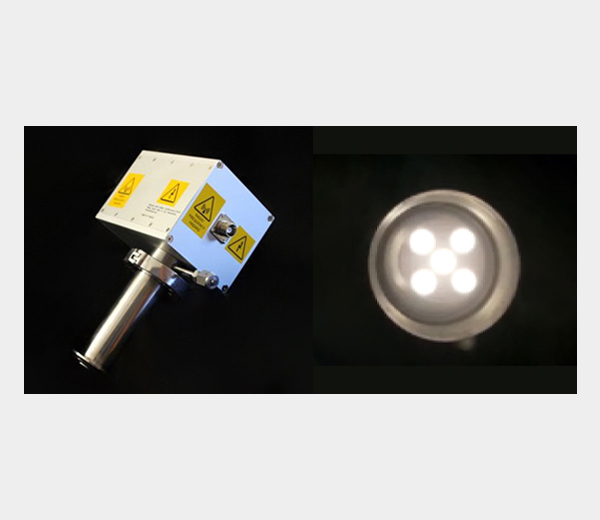

SERIES 50

- NW50 vacuum flange 에 연결됨

- ALD, Oxidation 및 PECVD에 적용

- 최대 8” wafer까지 적용 가능

● Series 50 Hollow Cathode Plasma Source 사양

• NW50 (KF50) vacuum connection.

• NW50 (KF50) nipple housing on request.

• 300 or 600 Watt maximum applied power.

• DC or 13.56 MHz RF operation.

• N, HN or DIN input voltage connectors, others on request.

• Male or female VCR gas input.

• Water cooling, 1-3 liters/min room temperature water (distilled or deionized preferable). Swagelok connections.

• Integrated matching box on request.

• 316 stainless is standard, but other cathode materials on request.

• Operation from 100 mTorr to > 10 Torr.

• Gases to date: NH3, N2, H2, Ar, O, NO, others possible depending on material compatibility.

• RF generator, matching network and matching network controller supplied on request. Will advise for modification of existing equipment.

-

8인치 wafer 위에 TiN film ALD 증착 공정에서 기존의 ICP 대신에

Series 50 Hollow cathode 플라즈마를 사용했을 떄의 결과(resistivity, GPC) 변화

ICP source: 1365 μΩ.cm, 0.94 A/cycle

Hollow cathord source: 330 μΩ.cm, 1.14 A/cycle -

Si3N4 film ALD 증착 공정에서 기존의 ICP 대신에 Series 50 Hollow cathode

플라즈마를 사용했을 떄의 결과(GPC, RI, 및 N/Si ratio) 변화 -

CCP를 적용한 Beneq system 과 Hollow Cathode 플라즈마를

적용한 Fiji system의 결과 비교

Hollow Cathode 플라즈마 소스가 CCP에 비해 Film conductivity 측면에서

더 좋은 결과를 나타내고 있음. -

-

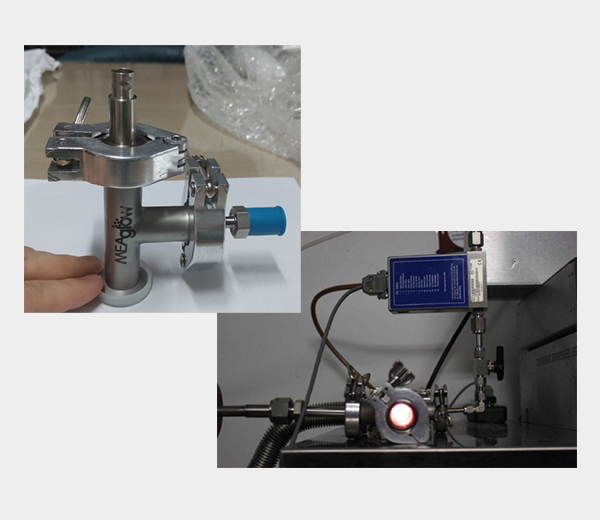

UHV SERIES

- 3 and 3/8” 또는 4 and 5/8” conflat vacuum flange에 연결됨

- 최대 8” wafer까지 적용 가능

● UHV series Hollow Cathode Plasma Source 사양

• Conflat fittings, sizing on request 3 and 3/8” and 4 and 5/8” most common.

• Nipple housing on request.

• 300 or 600 Watt maximum applied power.

• DC or 13.56 MHz RF operation.

• N, HN or DIN input voltage connectors, others on request.

• Male or female VCR gas input.

• Water cooling, 1-3 liters/min room temperature water (distilled or deionized preferable). Swagelok connections.

• Integrated matching box on request.

• 316 stainless is standard, but other cathode materials on request.

• Operation from 100 mTorr to >10 Torr.

• Gases to date: NH3, N2, H2, Ar, O, NO, others possible depending on material compatibility.

• RF generator, matching network and matching network controller supplied on request. Will advise for modification of existing equipment.

-

TiN film ALD 증착 공정에서 기존의 ICP 대신에 UHV series Hollow cathode

플라즈마를 사용했을 떄의 결과(resistivity) 변화

ICP source (15nm) : 970 μΩ.cm

ECS Journal of Solid State Science and Technology, 3 (2014) P253

ICP source (20 nm) : 145 μΩ.cm

J. Vac. Sci. Technol. A 32 (2014) 031506

HCP source: 57 μΩ.cm -

LARGE AREA

- 12” wafer 에 적용

● LARGE area Hollow Cathode Plasma Source 사양

• Conversion of commercial and home built ALD systems.

• 300 and 600 watt systems , higher power on demand, a 3 kilowatt , 12” source

• 12” wafer diameter, plus larger on request.

• 300 watt systems may not require water cooling

• Oxides, nitrides, other

• Low oxygen contamination (no dielectrics)

• Cost effective

• High electron density – similar to or greater than inductively coupled and microwave plasma sources, up to 1013 cm-3 for some plasma conditions.

• Wide range of operating pressures (eg. from <50 mTorr to >5 Torr).

• Improved growth per cycle for many material systems

-

12inch diameter Hollow Cathode, 3000 W operation

Series 16

- NW16 vacuum flange 에 연결됨

- 최대 4” wafer까지 적용 가능

● Series 16 Hollow Cathode Plasma Source 사양

• Max. 80 watt operation continuously, up to 100 watt in pulse mode.

• No water cooling. The system can get hot and present a heat hazard, air cooling can moderate this.

• Suitable for 2 to 4” wafers and smaller test samples.

• Oxides, nitrides, other

• Low oxygen contamination (no dielectrics)

• Cost effective

• High electron density of 1012 cm-3 or higher dependent on conditions.

• Wide range of operating pressures (eg. from < 200 mTorr to > 10 Torr).

• Improved growth per cycle for many material systems